Our Machines

Our facilities house extensive in-house capabilities — from stamping, casting, rolling, cutting, and pressing to high-precision lasers and plating lines — supported by state-of-the-art additive manufacturing, atomisation, and inspection technologies. Together, these systems enable us to produce consistently high-quality components and precious metal products with exceptional accuracy, repeatability, and sustainability.

Precious Metal Additive Manufacturing

Our cutting-edge precious metal additive manufacturing technology is your gateway to precision and innovation in 3D printing.

We utilise world-class equipment to produce complex, high-quality components in gold, silver, platinum, and palladium.

Current equipment on-site includes:

2× EOS M080 3D printing machines, 2× EOS M100 machines, and 1× Renishaw AM system.

Advanced Atomisation Technology

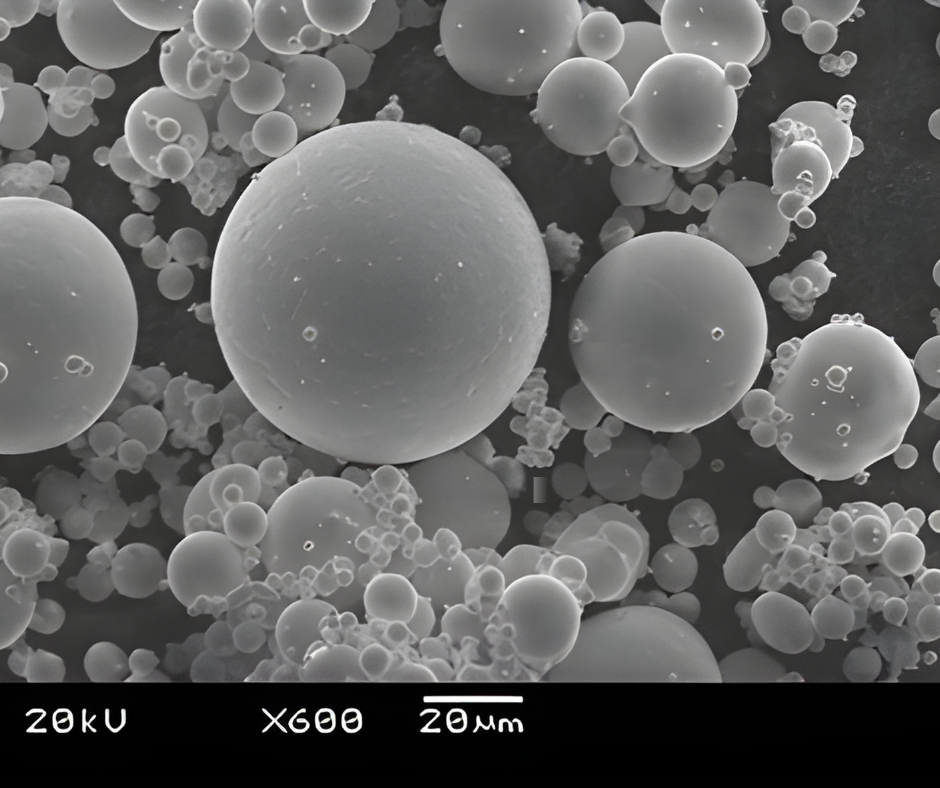

Gas Atomisation

A premier process for creating high-quality, spherical metal powders, Ideal for additive Manufacturing and Metal injection molding, this technique is renowned for producing powders with exceptional characteristics

- Particle Size: Predominantly less than 200 microns for precise applications

- Purity Level: Achieving less than 30 parts per million (ppm) – Highest quality

- Flowability: Outstanding, facilitating ease of use in various applications

- High production Yield: With optimisation, yields can surpass 70%, making it an efficient choice

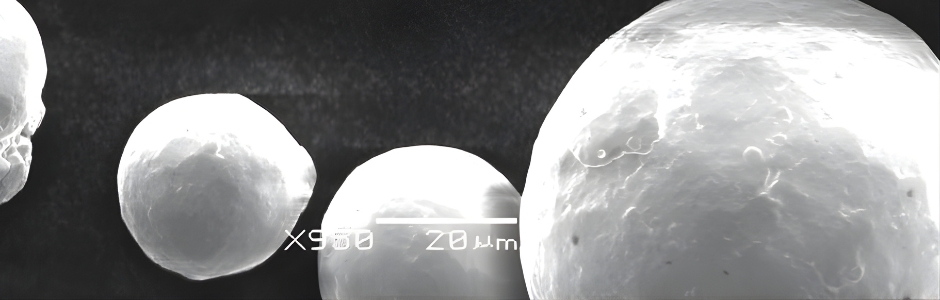

Ultrasonic Atomisation

In our pursuit of excellence we also employ ultrasonic atomisation. This method is tailored for the production of ultra fine, spherical powders, particularly suited for small-scale, high-precision tasks. The process involves:

- Advanced Technique: Utilising an electric arc from a tungsten electrode to melt materials.

- Innovative Method: Feeding wire or rod into the arc, with ultrasonic vibrations breaking the molten material into fine droplets.

- Particle Size Distribution (PSD): Achieving a narrow range of 0-100 microns for specific application requirements.

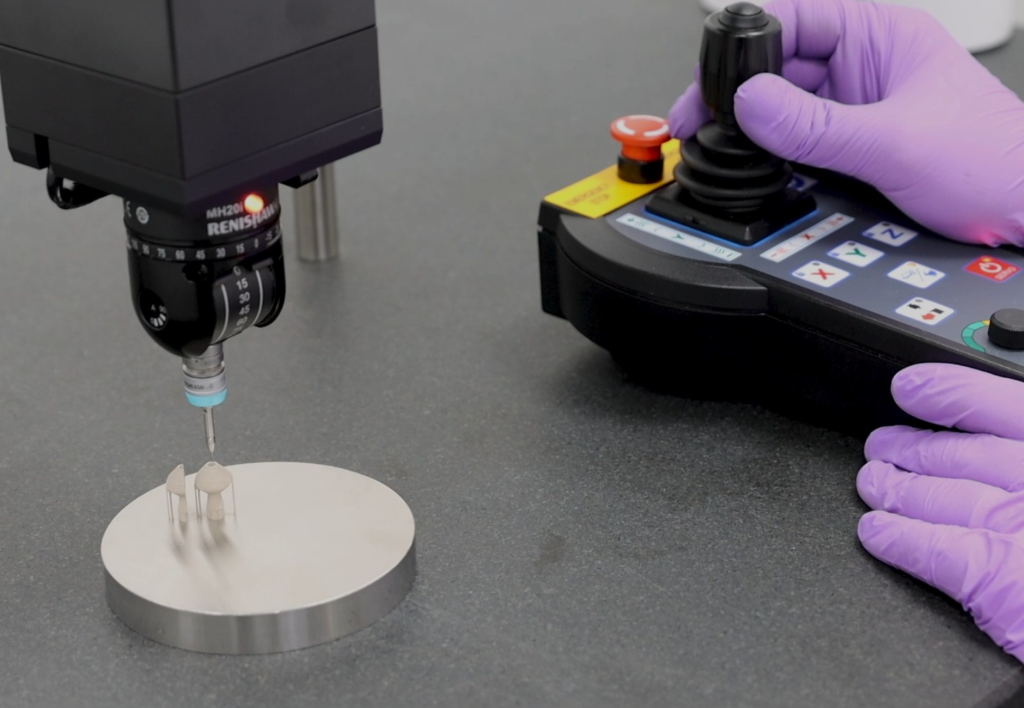

Quality Control and Inspection

Our facility includes a Coordinate Measuring Machine (CMM) — a high-precision system that measures 3D geometry to ensure every part meets exact specifications.

This allows us to verify accuracy for 3D-printed components used in aerospace, automotive, and medical sectors where precision is critical.

Sustainability in Manufacturing

Our Indutherm AUG1000 atomiser features an energy-efficient design and optimised resource use, aligning with our commitment to sustainability.

This ensures minimal material waste and reduced environmental impact across all production stages.

Partner with Cookson Industrial

```html

Choosing Cookson Industrial means working with a UK-based manufacturer and global supplier dedicated to technology, sustainability, and precision in every process.

Our expertise allows us to lead in the development of next-generation precious metal products built to the highest standards of quality and performance.

Contact us today to discuss your project requirements and discover how our technologies can power your next innovation, wherever you are in the world.

Contact Us

Speak with our team today to discuss how our technologies can support your manufacturing and design needs.