Contact Us

- +44 (0) 121 233 8191

- sales@cookson-industrial.com

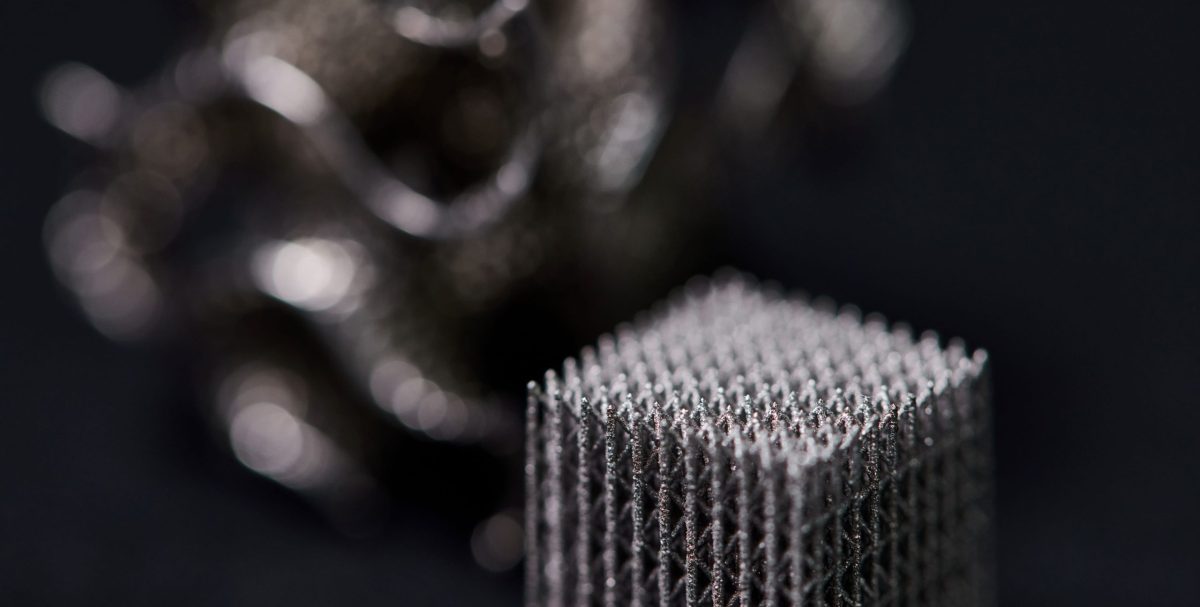

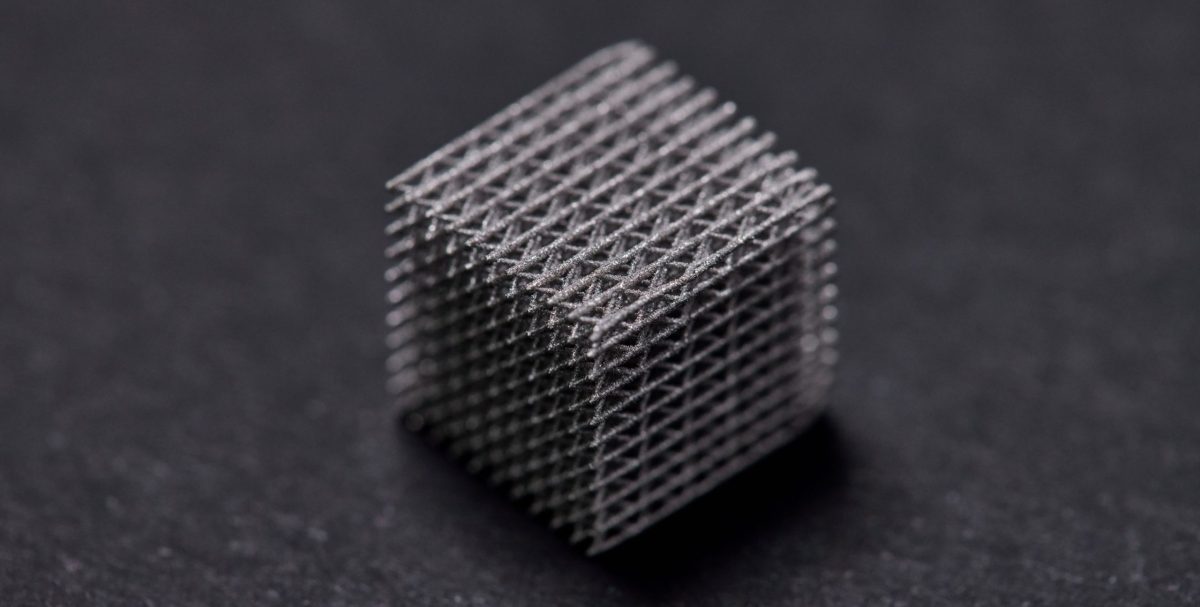

Additive Manufacturing

Our cutting edge precious metal additive manufacturing solutions is your gateway to unprecedented quality and innovation in the realm of 3D printing. At Cookson Industrial, we are at the forefront of precious metal additive manufacturing, leveraging advanced technology, expertise, unparalleled precision and efficiency. With true design flexibility, we deliver end to end solutions no matter what your specific customer needs for any industry.

With infinite design possibilities to evolve what already exists or create the next innovation within your industry. Create complex geometries that mimic nature to maximise output and reduce costs of producing your key components.

Explore our Benefits

- Leading Expertise

- Cutting Edge Technology

- Comprehensive Solutions

- Quality Assurance

- Industry Leading Support

Leading Expertise

With decades of experience, a team of experts and specialists in precious metal additive manufacturing, we bring a wealth of knowledge and experience to every project. From intricate designs to small production runs, our experts are equipped to handle diverse challenges, providing you with application support.

Cutting Edge Technology

We understand that every project is unique, which is why we offer a range of additive manufacturing solutions to suit your specific requirements. Whether you need project management, end-use production parts or our near net shaping techniques, we have the expertise and capabilities to deliver results that meet your objectives and exceed your expectations.

Comprehensive Solutions

We understand that every project is unique, which is why we offer a range of additive manufacturing solutions to suit your specific requirements. Whether you need project management, end-use production parts or our near net shaping techniques, we have the expertise and capabilities to deliver results that meet your objectives and exceed your expectations.

Quality Assurance

We understand that every project is unique, which is why we offer a range of additive manufacturing solutions to suit your specific requirements. Whether you need project management, end-use production parts or our near net shaping techniques, we have the expertise and capabilities to deliver results that meet your objectives and exceed your expectations.

Industry-Leading Support

Our commitment to customer satisfaction doesn’t end with the completion of a project. We provide ongoing support and guidance to help you navigate the complexities of additive manufacturing and maximise the benefits of our services for your business.

What we can offer

We can offer you production-ready components, intricate geometries, and samples in a variety of precious metal alloys. Additionally, we have in-house capabilities that allow us to produce part specific jigs and fixtures to aid manufacturing quickly and accurately. With a multitude of machines, extensive industry experience, and a proficient CAD team who are also skilled in engineering drawing interpretation, we can provide comprehensive Additive Manufacturing solutions from ideation to creation.

Mass Customisation

- Tailor products and processes to meet specific client needs.

- Offer personalised solutions for diverse applications.

- Enhance customer satisfaction through unique, customised offerings.

Shorter Time-to-market

- Accelerated product development and delivery cycles.

- Respond swiftly to market demands and trends.

- Enable customers to capture hype cycles.

- Gain a competitive edge by rapidly bringing innovations to market.

No Tooling Costs

- Eliminate upfront expenses associated with traditional manufacturing tooling.

- Reduce financial risk and enable cost-effective production runs for low-high volume applications.

Weight Reduction

- Topology optimisation by utilising DFam (Design for Additive Manufacturing) methods.

- Providing benefits such as light weight designs to reduce costs and/or increase application performance.

Supply Chain Simplification

- Streamline procurement processes and vendor management.

- Reduce complexity in sourcing raw materials and components.

- Enhance efficiency and reduce lead times by optimising the supply chain.

- Enable onshore manufacturing.

Our Capabilities

Precious Metal Powder Production and Sales

- With existing alloys

- Bespoke Alloys

- Full Chain of custody Materials

Precious Metal Refining and Recycling

- Scrap metal recycling, melt & assay analytical services

- Gold & Silver Refining with LBMA accreditation

- Metal account trading with metal finance options

Heat Treatment

- Stress relief and microstructure refinement

- Improves metal resistance, mechanical performance whilst reduces wear and damage on finished surface

- increased corrosion resistance temperature resistance, ductility and strength.

- Ability to improve density and mechanical performance

Precious Metal Parameter/Application

- Developed parameters for existing alloys

- Development of parameters new alloys

- Development of parameters specific application/geometry

Polishing/Finishing

- An end product with a high-quality finish

- Various polishing finishes to your choice

Wire Electro Discharge Machining (WEDM)

- Extremely fine resolution cuts

- Creates extremely smooth surfaces

- Holds close tolerances

3D Printing

- Unique 3D Printing service -laser powder bed fusion

- STL file analysis, quotation and print.

- 2D line drawing or image conversion to CAD.

- Design Alterations

- Precious Metal Alloy development

Precious Metal Powder Production and Sales

- With existing alloys

- Bespoke Alloys

- Full Chain of custody Materials

Heat Treatment

- Stress relief and microstructure refinement

- Improves metal resistance, mechanical performance whilst reduces wear and damage on finished surface

- increased corrosion resistance temperature resistance, ductility and strength.

- Ability to improve density and mechanical performance

Wire Electro Discharge Machining (WEDM)

- Extremely fine resolution cuts

- Creates extremely smooth surfaces

- Holds close tolerances

3D Scanning

- Swift and efficient process for capturing high-resolution scans of any physical 3D object within specified dimensions

- Get exact digital replicas of treasured objects

- Quick and easy service

- High quality & Accuracy

Precious Metal Parameter/Application

- Developed parameters for existing alloys

- Development of parameters new alloys

- Development of parameters specific application/geometry

Polishing/Finishing

- An end product with a high-quality finish

- Various polishing finishes to your choice

Experience the future of manufacturing with Cookson Industrial’s Precious Metal Additive Manufacturing Products and Service. Contact us today to learn more about how we can provide the best solutions and help you transform your ideas into reality with precision, efficiency, and innovation.