Why Choose Us

Let’s Start Work Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

- +44 (0) 121 233 8199

- industrial@cooksongold.com

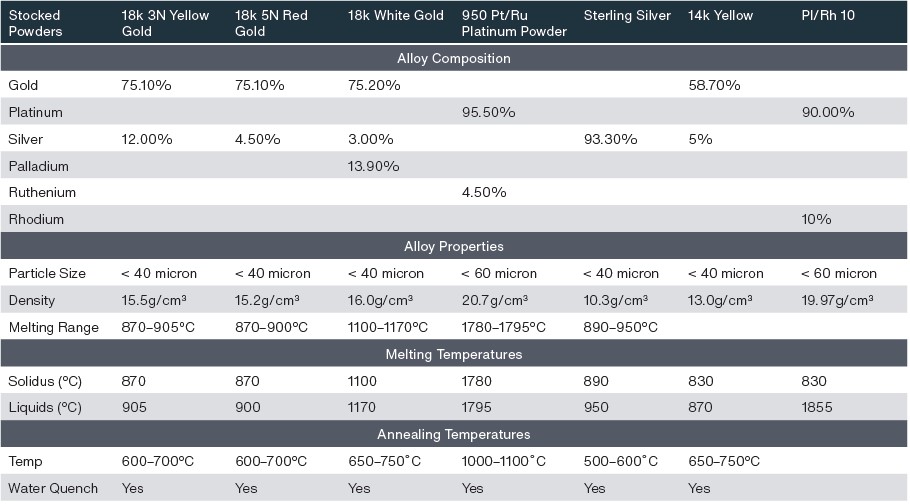

Advanced Precious Metal Powders

Powder Properties

Powder and Metalurgy analytical capabilties

Scanning Electron Microscope (SEM)

- Equipped with an Oxford Inca Energy-Dispersive X-ray Spectroscopy (EDX) system to analyse the surface texture, morphology and microstructural characterisation

- EDX to visualise the elemental composition and understanding the correlation between elemental composition and microstructure.

Electron BackSatter Diffraction (EBSD)

- Mapping system for the characterisation of grain boundary types, angles, and distributions

- Providing insights into the material’s mechanical and thermal properties.

Microtrac S3500

- Three precisely placed red laser diodes to accurately characterise particle size for a diverse range of applications by utilisting the proven theory of Mie compensation for spherical particles and the proprietary principle of modified Mie calculations for non-spehrical particles.

- The S3500 measures particle size from 0.02 to 2800 micrometer

Panalytical Zetium Spectometer

- X-ray fluoresence spectrometry (XRF) is capable of elemental analysis of a wide range of materials including solids, liquids and loose powders.

- Designed to meet the most demanding process control & R&D applications

- The Zetium spectrometer uses innovative features for sub ppm to percentage analysis

Alicona InfiniteFocus System

- The Optical 3D Surface Measurement to quantitatively assess the texture and roughness of surfaces

- Crucial in industries such as manufacturing, quality control, and research and development.

Freeman Technology FT4

- Characterising the rheology or flow properties of powder

- FT4 includes a shear cell for measuring the powders shear strength to quantify how a powder shears with respect to surfaces of process equipment

- The system measures bulk properties such as density, compressibility and permeability.

Perkin Elmer ICP Optima 7300V

- Carrying out simultaneous measurement and coverage across the entire wavelength range (UV and Visible).

- More than 73 elements can be measured in seconds with all raw spectral data stored with full reprocessing capabilities. This allows sample results to be evaluated under different processing conditions, reducing the need to re-run samples.

Energy-Dispersive X-ray Spectroscopy (EDX)

- The integrated analytical EDX into SEM provides valuable information about the elemental composition of a sample by detecting characteristics x-rays emitted from the samples when it is bombarded with high-energy electrons in the SEM. It provides qualitative information about the present in the sample.

- It can identify and map the distribution of different elements across the sample surface, allowing us to visualize the elemental composition and understanding the correlation between elemental composition and microstructure

Gas Atomisation

- A premier process for creating high-quality, spherical metal powders,

- Ideal for additive Manufacturing and Metal injection molding, this technique is renowned for producing powders with exceptional characteristics

- Particle Size: Predominantly less than 200 microns for precise applications

- Purity Level: Achieving less than 30 parts per million (ppm), ensuring top-tier quality.

- Flowability: Outstanding, facilitating ease of use in various applications

- High production Yield: With optimisation, yields can surpass 70%, making it an efficient choice

Ultrasonic Atomisation

In our pursuit of excellence, we also employ Ultrasonic Atomisation. This method is tailored for the production of ultra-fine, spherical powders, particularly suited for small-scale, high-precision tasks. The process involves:

- Advanced Technique: Utilising an electric arc from a tungsten electrode to melt materials.

- Innovative Method: Feeding wire or rod into the arc, with ultrasonic vibrations breaking the molten material into fine droplets.

- Particle Size Distribution (PSD): Achieving a narrow range of 0-100 microns for specific application requirements.