Precious Metal Additive Manufacturing

Precious Metal 3D Printing

Gold Additive Manufacturing

Silver 3D Printing

Platinum Additive Manufacturing

Industrial Precious Metal 3D Printing

UK Precious Metal 3D Printing Supplier

Cookson Industrial stands at the forefront of precious metal additive manufacturing technology. With over 15 years of experience in precious metal AM, we deliver comprehensive end-to-end services that transform your innovative concepts into reality.

Our expertise in precious metal 3D printing unlocks infinite design possibilities, enabling you to create complex geometries and intricate structures that were previously impossible with traditional manufacturing methods.

From initial concept to final production, we provide the technical expertise, cutting-edge equipment, and industry knowledge to bring your ambitious projects to life.

Why Choose Us

Leading Expertise

Decades of experience in precious metal manufacturing and additive technology

Cutting-Edge Technology

State-of-the-art equipment and innovative processes for superior results

Comprehensive Solutions

End-to-end services from design to production and finishing

Industry

Leading Support

Dedicated technical support and consultation throughout your project

3D print your designs in Gold,

Silver,

Platinum

and more with Cookson Industrial.

What We Offer

Our comprehensive suite of services covers every aspect of precious metal additive manufacturing, ensuring your project succeeds from concept to completion.

- Production-ready components with guaranteed quality

- Expert CAD design team for optimization

- Custom jigs and fixtures for complex assemblies

- Material samples in various precious metal alloys

- Prototyping and small-batch production

- Post-processing and finishing services

Our Capabilities

Comprehensive services to support every aspect of your additive manufacturing journey

Powder Production & Sales

High-quality precious metal powders for consistent, reliable printing results

Heat Treatment

Precise thermal processing to optimise material properties and performance

WEDM Services

Wire electrical discharge machining for precision finishing and tight tolerances

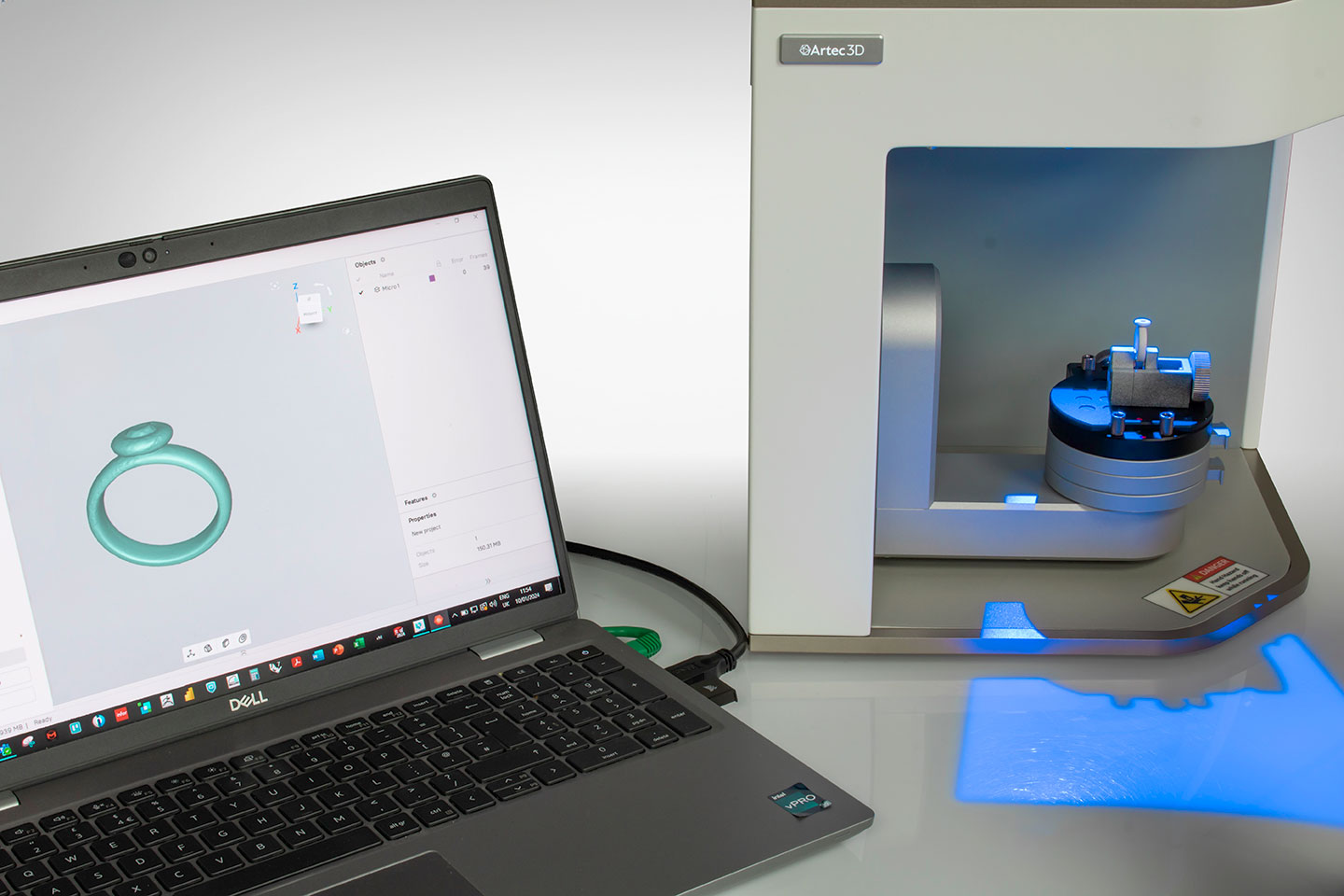

3D Scanning

Advanced scanning capabilities for reverse engineering and quality control

Polishing & Finishing

Professional finishing services to achieve the perfect surface quality

Parameter Development

Custom process parameters optimised for your specific applications

Applications Gallery

Explore the diverse range of components we’ve successfully manufactured

Lattice Structures

Alloy: (Gold Alloy 18K)

Parts: (24 components)

Build Time: (8 hours)

Gyroid Patterns

Alloy: (Platinum 950)

Parts: (12 components)

Build Time: (6 hours)

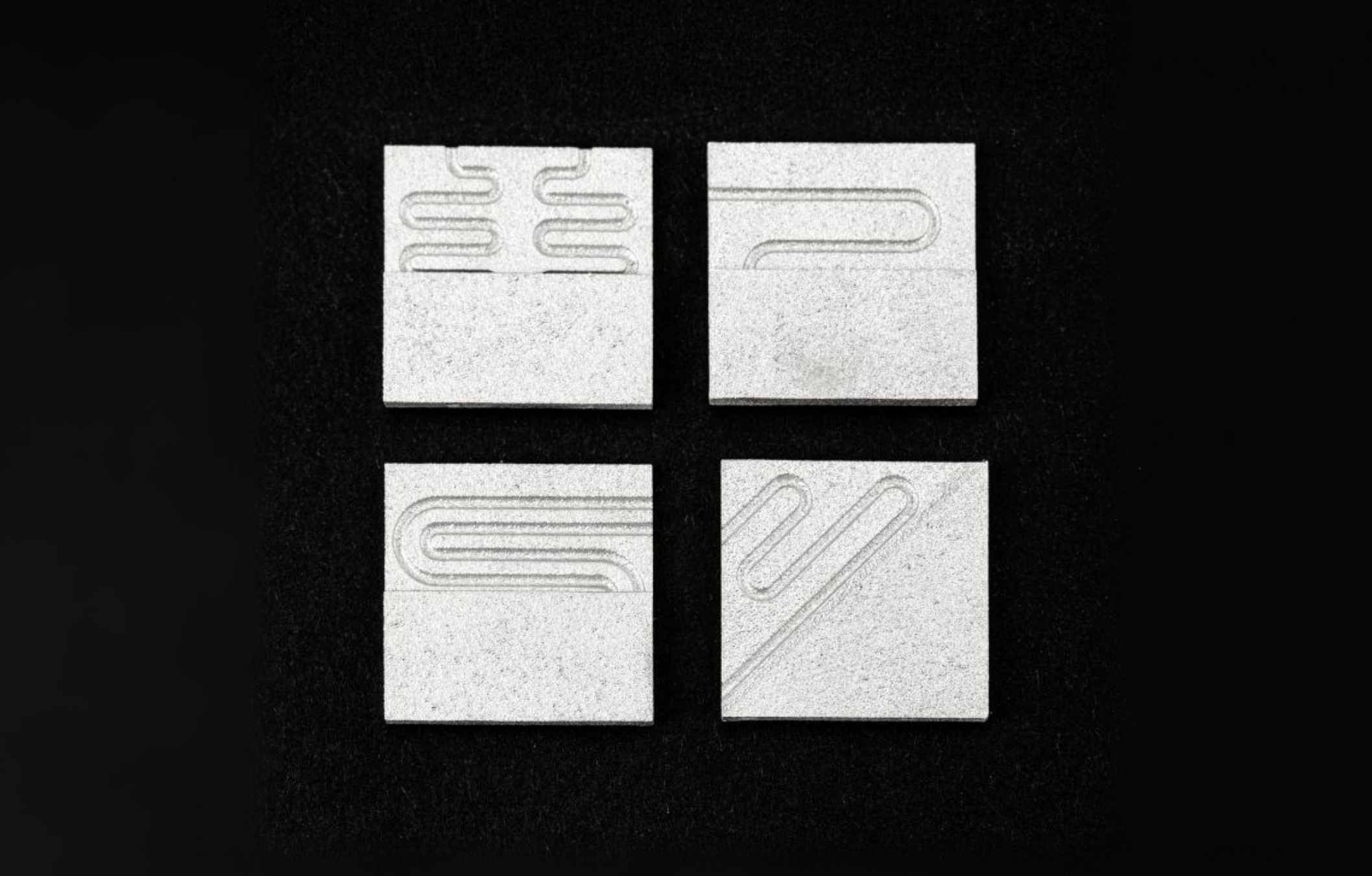

Heat Sinks

Alloy: (Silver Alloy)

Parts: (6 components)

Build Time: (4 hours)

Silver Chess Pieces

Alloy: (Gold/Silver Mix)

Parts: (32 components)

Build Time: (24 hours)

Bentley Partnership Case Study

See how Cookson Industrial supported Bentley with innovation in precious metal additive manufacturing, delivering luxury automotive components that meet the highest standards of quality and precision.

Our collaboration resulted in groundbreaking applications of 3D printing technology in luxury automotive manufacturing, setting new benchmarks for the industry.

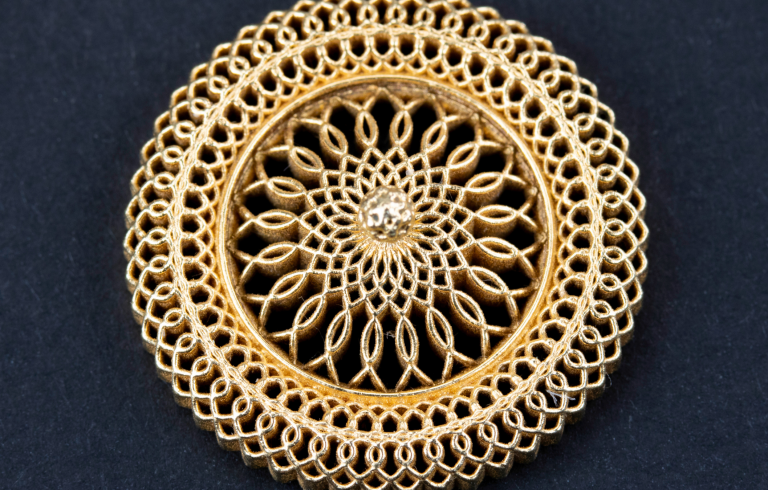

Boltenstern x Cookson Industrial Case Study

ChatGPT said:

We partner with visionary luxury houses like Boltenstern to realise jewellery designs that traditional manufacturing simply can’t achieve. By 3D printing in recycled gold, silver and platinum, we unlock intricate, woven and highly customisable structures that are both visually striking and incredibly comfortable to wear. Every piece is then hand-finished by skilled jewellers to meet the highest standards of luxury, while our 100% recycled precious metal powders support a more responsible approach to fine jewellery.

Find out how precious metal additive manufacturing is reshaping what’s possible in high-end design.

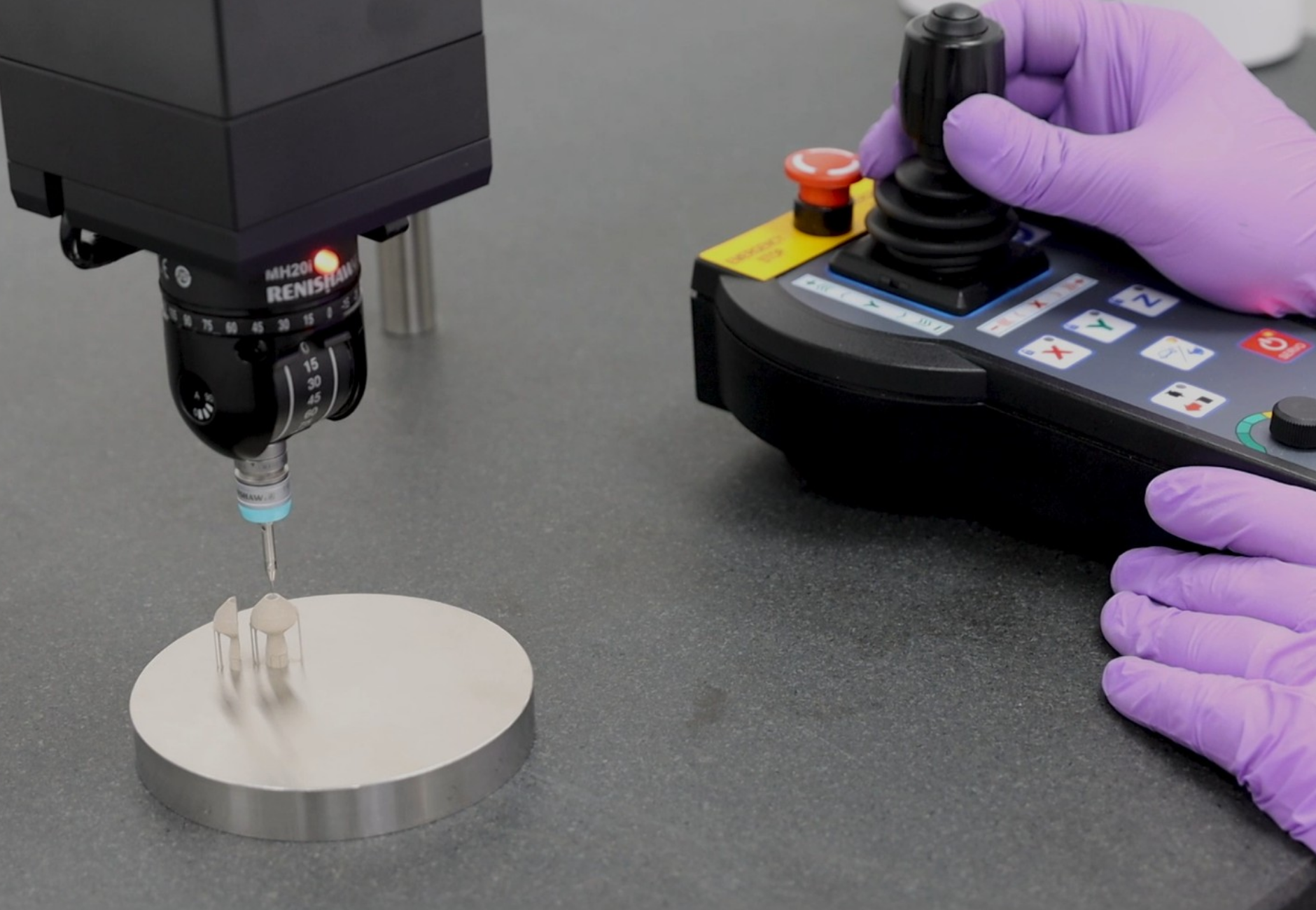

Renishaw x Cookson Industrial Case Study

Cookson Industrial partnered with Renishaw to make one of the world’s most expensive metals, platinum rhodium, commercially viable for additive manufacturing. By adapting Renishaw’s RenAM 500S Flex system, Cookson Industrial was able to minimise powder waste and significantly reduce production costs.

The result was a 95% reduction in trapped powder, saving thousands of pounds per build and unlocking new opportunities for high-value industrial applications. Discover how this breakthrough is redefining precious metal manufacturing in our full case study.

Get in Touch

Contact us to enquire about what you can achieve in Precious Metal 3D printing.

Why Choose Cookson Industrial?

Trusted Quality

Every tube is manufactured and inspected with rigorous quality controls to ensure precision and consistency.

Global Supply Network

From our UK base, we supply tubing efficiently across Europe and worldwide.

Industry Expertise

With decades of metallurgical experience, our team provides both technical expertise and practical support.

Customisation Options

We can develop tailor-made tubing in different diameters, lengths, and alloys to suit your project.

Sustainable Commitment

Where possible, we use recycled and responsibly sourced metals to support greener manufacturing practices.